Our capabilities

Design R&D

Our R&D department comprises designers and engineers who work together daily to create innovative and functional products that prioritise the user experience. They aim to meet the requirements of our clients and the needs of end-users. Our innovation process starts with in-depth research and analysis focused on understanding patient journeys, tracking market trends, and identifying emerging opportunities.

Some of our key R&D capabilities include:

- Ergonomics and human factors studies

- Concept industrialization

- Design to cost

- Product life cycle analyses

- Fused Deposition Modeling (FDM) prototyping

- Design to value

Notre méthodologie

Regulatory

SGH Medical Pharma has a track record of 135 CE-marked devices, a DMF submission to the FDA and is in the process of applying to UKCA.

We draft technical documentation for CE marking and keep it up to date with regulatory changes. We also assist our clients with the transfer of intellectual property by drafting patents and trademarks and guiding them in change control management.

Quality

Quality management involves overseeing every stage of the process, from identifying customer needs to shipping the drug administration system, including development and production. We aim to ensure strict adherence to standards and regulations applicable to medical devices and primary packaging throughout the product lifecycle. Our commitment is reflected in all aspects of our operations, with ISO 13485, ISO 15378, and ISO 14001 certifications.

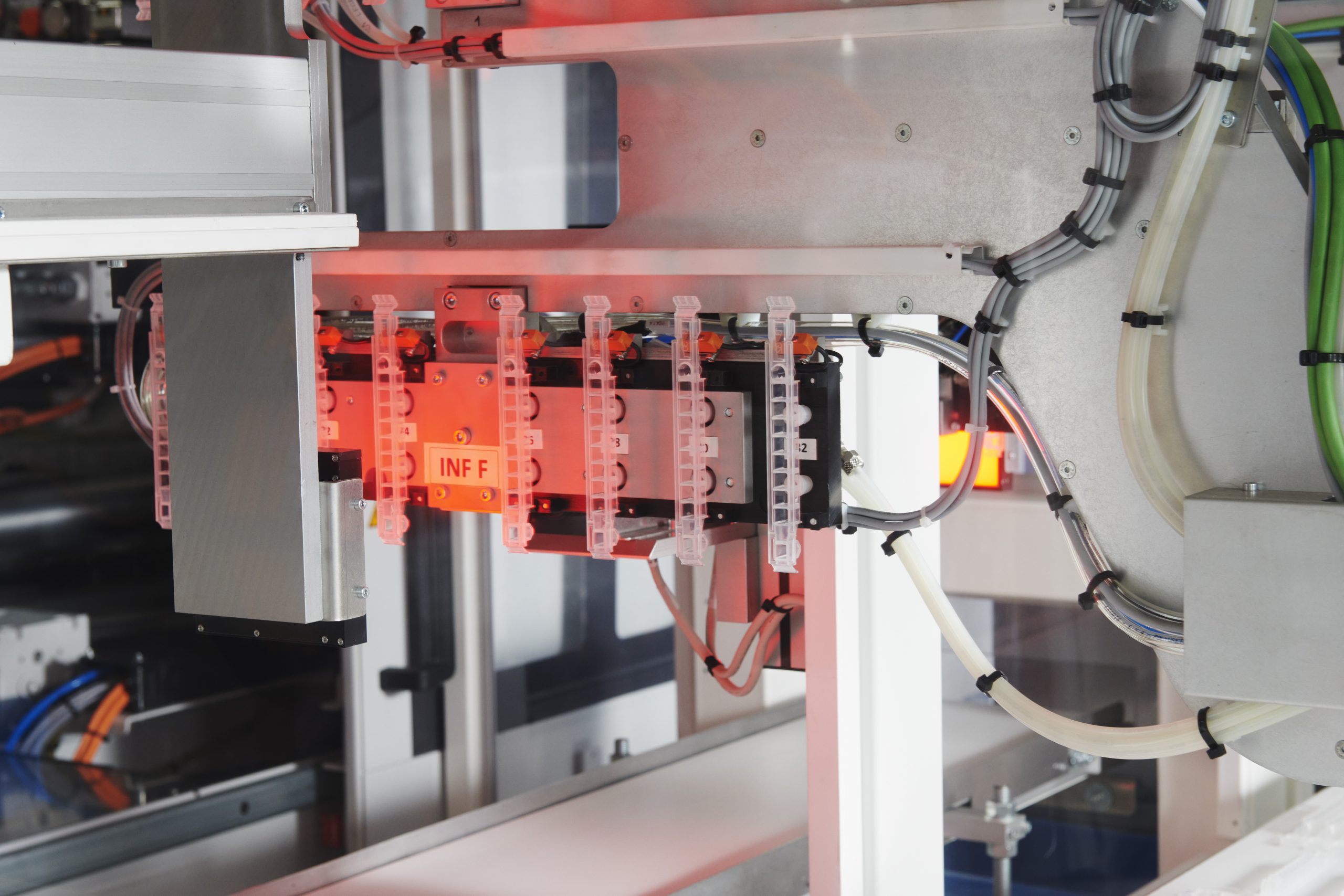

Industrialization

Our industrialization centre is focused on developing, improving, and implementing specialized equipment. This includes assembly and inspection machines, automated workstations, and marking devices. We design, develop, and optimize our industrial tools to meet the specific requirements of medical devices and their assembly process. Our in-house expertise allows us to produce customized items while maintaining cost control.

Our production spaces are configured for lean manufacturing (production time optimization). We are equipped with :

– ISO8-7, DNA RNA free cleanrooms

– Fully automated assembly workshops include marking.

Besides, our packaging and finishing lines are constantly reviewed and improved to maintain a high level of quality and performance.